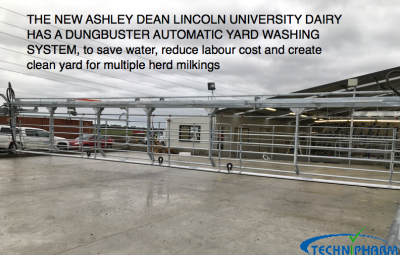

Dungbuster® The Smart Way To Wash Your Yard

Environmental Goal; Use Less Water, Staff Health And Wellbeing, Leverage Skill Base, Decarbonise

Dungbuster – Automated Dairy Shed Cleaning by Technipharm

Claim back those daily hours and cost of washing the yard

Managing effluent in dairy sheds is a daily challenge for farmers. Technipharm’s Dungbuster automatic yard washing system revolutionizes shed hygiene with a fully automated, reliable cleaning solution designed to reduce labour, improve animal health, and help meet regulatory compliance. Whether youre operating a herringbone or rotary system, Dungbuster keeps your shed clean and safe with minimal input.

How Dungbuster Works

Dungbuster is installed at the backing gate and automatically scrapes and clean the yard . The system operates as you milk the cows, every time the gate moves the Dungbuster cleans, ensuring continuous cleanliness without the need for manual labour. Designed with durability and simplicity in mind, Dungbuster works reliably in even the harshest shed environments.

Benefits of the Dungbuster System

Labour Savings: Automate one of the most unpleasant daily tasks.

Improved Cow Health: Cleaner floors reduce hoof problems and lower the risk of mastitis.

Environmental Compliance: Helps manage effluent in line with dairy industry standards.

Custom Fit: Works with both herringbone and rotary sheds.

Low Maintenance: Built tough with minimal moving parts.

Dungbuster vs Manual Cleaning

Traditional effluent cleaning methods are time-consuming and inconsistent. With Dungbuster, cleaning becomes automatic, consistent, and more effective. Less standing effluent means fewer slip risks for both cows and workers, and a healthier environment overall.

Dairy Shed water use and FDE

How much water is used in the shed impacts on how much FDE is produced, shed washing water is the largest contributor to FDE, so reducing water use reduces fresh water use AND FDE and related storage required, big savings can be obtained here by using Dungbuster ( source Environment court statement of evidence)

Trusted by New Zealand Farmers

Dungbuster is proudly used across New Zealand by forward-thinking farmers who value smart, efficient solutions. With years of proven performance in the field, the system continues to be a reliable partner in dairy shed hygiene.

Get a Cleaner Shed with Less Effort

Upgrade your dairy operation today with Dungbuster – the automated shed cleaning system built to make your job easier and your cows healthier.

Contact Technipharm to learn more, request a demo, or speak with a specialist.

How much time do you spend washing down your yard? Time is money, what else could you be doing? Increase your net profit with this one off investment. Daily costs will reduce want to know how much?

https://technipharm.co.nz/dungbuster-water-labour-saving

Environmental responcibility, fancy the idea of less effluent? Less worry, more reliability? One of the byproducts of dairy farming is effluent. Most farmers see this as a nuisance; however in reality its free fertilizer and treating it as such would be a great start to get better results out of it. Like fertilizer wasting it, costs. For starters it is beneficial to stop producing large volumes of water in the production of milk, why do we need thousands and thousands of litres of water to wash a yard? Basically we just do it because every one does it and we have always done it that way. Leading companies in yard and gate design use Dungbuster, Leask engineering, Don Chapman, Herdflow, Michael Bloemen to name a few... All that water (which you had to pump out of a well or creek) turns into effluent, which you will have to pump (again) out to pasture. When its wet and soils are saturated that water causes you to have to reduce application rates and as such increases the area you apply the effluent to, all of which cost money and soaks up time. There are many water saving features one can install in the dairy, to name one a Dungbuster® automatic yard washing system which will reduce water use washing the yard by up to a good 40% if not more. That is right up to 40%, 40% less to pump out of the ground, 40% less washing pump running and 40% less effluent not a bad start, right? On top of that you will achieve electricity savings and time savings (the average yard takes a full 120 hours per year to be washed! 120 hours is 3 weeks labour!!!!! Yes 3 weeks. Reducing the environmental impact of your farm operation means de carbonising Reduced the carbon impact also means you may be a step closer to qualifying for incentive payments from your milk company.

Reduce emisions by washing urine away quickly behind the cows makes sense, most cows urinate while milking and this turns into N oxide a greenhoiuse gas, diluting it and washing it away will reduce the impact and keeps more N in your circular system.

Wanting to go Greenwash? The Greenwash Dungbuster ™ auto yard washing system. Switch between greenwash and clean wash when needed and have a Fonterra/ MPI compliant green wash system.